Top 5 Balancing Machines / Dynamic Balancing Machines

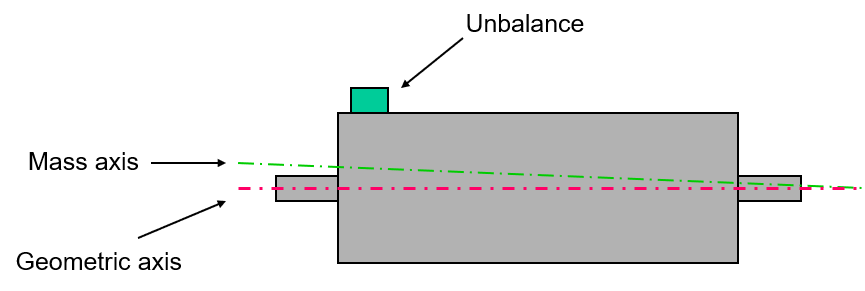

A balancing machine measures static or dynamic unbalance. A typical Balancing Machine has 2 pedestals, with some kind of roller bearings on top. A rotor is placed on these roller bearings so that the rotor can rotate easily. A belt is slung around the rotor and driven by an electric motor to make the rotor spin. The terms "soft-bearing" Balancing Machine and "hard-bearing" Balancing machine indicate how the rotor is supported on the pedestals.

If the rotor support can move freely (soft), the machine is called a soft-bearing balancing machine.

In soft-bearing machines this will lead the rotor support to move (vibrate). The movement is measured with vibration sensors.

If the rotor is supported in rigid fashion (hard), the machine is called a hard-bearing balancing machine.

In hard-bearing machines the rotor support is rigid. the spinning rotor cannot vibrate; instead the unbalance forces are measured with force sensors (not vibration sensors).

The most common Balancing Machines

Horizontal balancing machines are making up 80% of the balancing machine market. These balancing machines are very versatile and can balance a wide range of rotors, from small dentist drills to large steam turbine generators,

Vertical balancing machines are are available in 1-plane balancing machines and 2-plane balancing machines. 2-plane vertical balancing machines are more universal than 1-plane balancing machines. Vertical balancing machines typically require a dedicated fixture to mount a specific rotor for balancing purposes.

Next are semi-automatic or fully-automatic balancing machines. These are typically dedicated to a specific rotor application, are more costly than standard manual balancing machines.

Modern balancing machines can measure 1-plane unbalance, 2-plane unbalance, and static/couple unbalance. However, static/couple unbalance is typically not measured directly but calculated from 2-plane unbalance.

Hard-bearing balancing machines are calibrated once, and can measure rotor unbalance without the need for trial runs. In simple terms, it is similar to a bathroom scale: After the scale has been calibrated (by the manufacturer), you simply step on the scale and it reads your weight.

Hard-bearing calibration is applicable to vastly different rotor geometries fitting the size, mass and speed envelope of a given machine. Hard-bearing calibration should be checked periodically, and if necessary a re-calibration should be performed.